Benefits of Vacuum Cast Coil Dry Type Transformers in Batch Production

When it comes to batch production, efficiency and reliability are key factors that can make or break a manufacturing company’s success. One crucial component in the production process is the transformer, which plays a vital role in converting electrical energy from one voltage level to another. In recent years, vacuum cast coil dry type transformers have emerged as a popular choice for batch production facilities due to their numerous benefits.

One of the main advantages of vacuum cast coil dry type transformers is their superior insulation properties. Unlike traditional transformers that use oil as a coolant and insulator, vacuum cast coil transformers are filled with epoxy resin, which provides excellent insulation against electrical arcing and short circuits. This not only enhances the safety of the production process but also reduces the risk of downtime and costly repairs.

| Type | Rated capacity (KVA) | Voltage combination(KV) | No-load losses(W) | Load losses(W) | No-load current (%) | Short-circuit impedance (%) |

| SC13-30 | 30 | 6,6.3,6.6,10,11/0.4 | 150 | 710 | 2.3 | 4.0 |

| SC13-50 | 50 | 6,6.3,6.6,10,11/0.4 | 215 | 1000 | 2.2 | 4.0 |

| SC13-80 | 80 | 6,6.3,6.6,10,11/0.4 | 295 | 1380 | 1.7 | 4.0 |

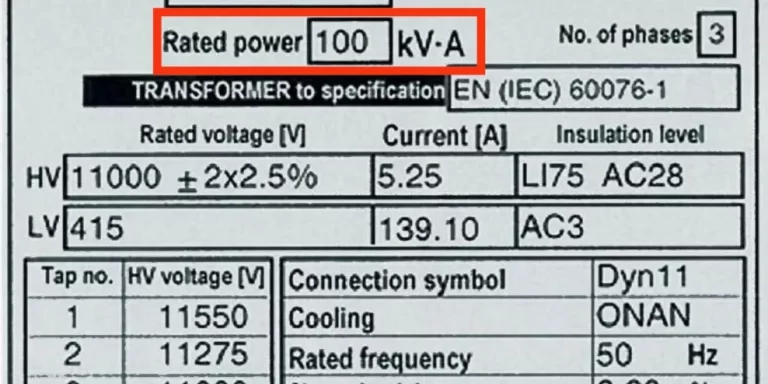

| SC13-100 | 100 | 6,6.3,6.6,10,11/0.4 | 320 | 1570 | 1.7 | 4.0 |

| SC13-125 | 125 | 6,6.3,6.6,10,11/0.4 | 375 | 1850 | 1.5 | 4.0 |

| SCB13-160 | 160 | 6,6.3,6.6,10,11/0.4 | 430 | 2130 | 1.5 | 4.0 |

| SCB13-200 | 200 | 6,6.3,6.6,10,11/0.4 | 495 | 2530 | 1.3 | 4.0 |

| SCB13-250 | 250 | 6,6.3,6.6,10,11/0.4 | 575 | 2760 | 1.3 | 4.0 |

| SCB13-315 | 315 | 6,6.3,6.6,10,11/0.4 | 705 | 3470 | 1.1 | 4.0 |

| SCB13-400 | 400 | 6,6.3,6.6,10,11/0.4 | 785 | 3990 | 1.1 | 4.0 |

| SCB13-500 | 500 | 6,6.3,6.6,10,11/0.4 | 930 | 4880 | 1.1 | 4.0 |

| SCB13-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1070 | 5880 | 0.9 | 4.0 |

| SCB13-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1040 | 5960 | 0.9 | 6.0 |

| SCB13-800 | 800 | 6,6.3,6.6,10,11/0.4 | 1210 | 6960 | 0.9 | 6.0 |

| SCB13-1000 | 1000 | 6,6.3,6.6,10,11/0.4 | 1410 | 8130 | 0.9 | 6.0 |

| SCB13-1250 | 1250 | 6,6.3,6.6,10,11/0.4 | 1670 | 9690 | 0.9 | 6.0 |

| SCB13-1600 | 1600 | 6,6.3,6.6,10,11/0.4 | 1960 | 11700 | 0.9 | 6.0 |

| SCB13-2000 | 2000 | 6,6.3,6.6,10,11/0.4 | 2440 | 14400 | 0.7 | 6.0 |

| SCB13-2500 | 2500 | 6,6.3,6.6,10,11/0.4 | 2880 | 17100 | 0.7 | 6.0 |

In addition to their superior insulation properties, vacuum cast coil dry type transformers are also highly resistant to environmental factors such as moisture, dust, and chemicals. This makes them ideal for use in batch production facilities where the operating conditions can be harsh and unpredictable. By choosing vacuum cast coil transformers, manufacturing companies can ensure that their production process remains uninterrupted and efficient, regardless of the external environment.

Another key benefit of vacuum cast coil dry type transformers is their compact and lightweight design. Traditional transformers can be bulky and heavy, taking up valuable space in the production facility and making them difficult to transport and install. In contrast, vacuum cast coil transformers are much smaller and lighter, allowing for easier handling and installation. This not only saves time and labor costs but also enables manufacturing companies to optimize their production layout and maximize their available space.

Furthermore, vacuum cast coil dry type transformers are known for their high efficiency and low maintenance requirements. The epoxy resin insulation used in these transformers has excellent thermal conductivity, allowing for efficient heat dissipation and preventing overheating. This results in lower energy consumption and reduced operating costs for the manufacturing company. Additionally, the sealed design of vacuum cast coil transformers eliminates the need for regular maintenance and refilling of oil, further reducing downtime and maintenance expenses.

In conclusion, vacuum cast coil dry type transformers offer a wide range of benefits for manufacturing companies engaged in batch production. From superior insulation properties and environmental resistance to compact design and low maintenance requirements, these transformers are a reliable and cost-effective solution for ensuring the smooth and efficient operation of production facilities. By investing in vacuum cast coil transformers, manufacturing companies can improve their overall productivity, reduce downtime, and enhance the safety of their production process.