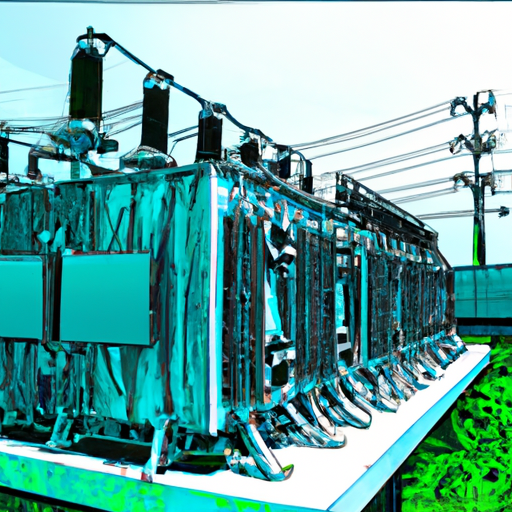

Benefits of Using Liquid Cooled Transformers in Industrial Applications

Liquid cooled transformers are a prestigious choice for OEMs and factories looking for reliable and efficient power distribution solutions. These transformers offer a range of benefits that make them ideal for industrial applications where high performance and reliability are essential.

One of the key advantages of liquid cooled transformers is their superior cooling capabilities compared to traditional air-cooled transformers. By using a liquid coolant such as mineral oil or silicone oil, these transformers are able to dissipate heat more effectively, allowing them to operate at higher power levels without overheating. This not only improves the efficiency of the transformer but also extends its lifespan, reducing the need for costly maintenance and repairs.

| Type | Rated capacity (KVA) | Voltage combination(KV) | No-load losses(W) | Load losses(W) | No-load current (%) | Short-circuit impedance (%) |

| SZ11-2000 | 2000 | 33,35/6.3,6.6,10.5,11 | 2300 | 19240 | 0.80 | 6.5 |

| SZ11-2500 | 2500 | 33,35/6.3,6.6,10.5,11 | 2720 | 20640 | 0.80 | 6.5 |

| SZ11-3150 | 3150 | 33,35/6.3,6.6,10.5,11 | 3230 | 24710 | 0.72 | 7.0 |

| SZ11-4000 | 4000 | 33,35/6.3,6.6,10.5,11 | 3870 | 29160 | 0.72 | 7.0 |

| SZ11-5000 | 5000 | 33,35/6.3,6.6,10.5,11 | 4640 | 34200 | 0.68 | 7.0 |

| SZ11-6300 | 6300 | 33,35/6.3,6.6,10.5,11 | 5630 | 36800 | 0.68 | 7.5 |

| SZ11-8000 | 8000 | 33,35/6.3,6.6,10.5,11 | 7870 | 40600 | 0.60 | 7.5 |

| SZ11-10000 | 10000 | 33,35/6.3,6.6,10.5,11 | 9280 | 48100 | 0.60 | 7.5 |

| SZ11-12500 | 12500 | 33,35/6.3,6.6,10.5,11 | 10940 | 56900 | 0.56 | 8.0 |

| SZ11-16000 | 16000 | 33,35/6.3,6.6,10.5,11 | 13170 | 70300 | 0.54 | 8.0 |

| SZ11-20000 | 20000 | 33,35/6.3,6.6,10.5,11 | 15570 | 82800 | 0.54 | 8.0 |

In addition to their superior cooling capabilities, liquid cooled transformers are also more compact and lightweight than their air-cooled counterparts. This makes them easier to install and transport, saving time and money for OEMs and factories looking to streamline their operations. The smaller footprint of liquid cooled transformers also allows for more flexible placement within a facility, making it easier to integrate them into existing power distribution systems.

Another benefit of using liquid cooled transformers in industrial applications is their ability to operate in harsh environments. The sealed design of these transformers protects them from dust, moisture, and other contaminants that can cause damage to electrical components. This makes them ideal for use in outdoor or industrial settings where exposure to the elements is a concern.

Liquid cooled transformers are also highly customizable, allowing OEMs and factories to tailor their design to meet specific power distribution requirements. This flexibility makes it easier to integrate these transformers into existing systems or to scale up their capacity as needed. With a wide range of options available, including different cooling fluids, insulation materials, and voltage ratings, OEMs and factories can choose the configuration that best suits their needs.

In addition to their technical advantages, liquid cooled transformers are also a cost-effective solution for industrial applications. While the initial investment may be higher than air-cooled transformers, the long-term savings in energy costs, maintenance, and repairs make them a more economical choice in the long run. By choosing a reliable supplier with a proven track record of delivering high-quality transformers, OEMs and factories can ensure that they are getting the best value for their investment.

Overall, the benefits of using liquid cooled transformers in industrial applications are clear. From their superior cooling capabilities and compact design to their ability to operate in harsh environments and customizable options, these transformers offer a range of advantages that make them a prestigious choice for OEMs and factories. By partnering with a reputable supplier who understands the unique needs of industrial customers, OEMs and factories can take advantage of the many benefits that liquid cooled transformers have to offer.