Benefits of Using Oil Cooled Transformers in Industrial Applications

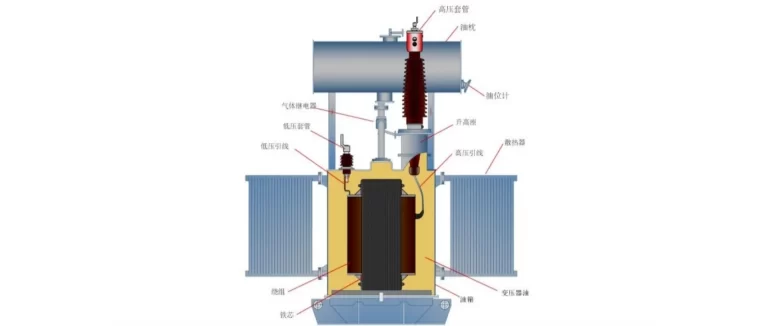

Oil cooled transformers are a crucial component in many industrial applications, providing a reliable and efficient way to step up or step down voltage levels. These transformers are designed to handle high power loads and are commonly used in factories, power plants, and other industrial settings. One of the main benefits of using oil cooled transformers is their ability to efficiently dissipate heat, ensuring optimal performance and longevity.

In industrial settings where power demands are high, transformers can generate a significant amount of heat during operation. Oil cooled transformers are specifically designed to address this issue by using oil as a coolant to absorb and dissipate heat more effectively than air-cooled transformers. This helps to maintain a stable operating temperature and prevent overheating, which can lead to equipment failure and downtime.

Another advantage of oil cooled transformers is their compact design, which allows for easy installation in tight spaces. This is particularly beneficial in factories and other industrial settings where space is limited and efficiency is key. Oil cooled transformers can be mounted on walls or floors, making them a versatile and space-saving solution for power distribution needs.

Furthermore, oil cooled transformers are known for their durability and reliability, making them a cost-effective choice for industrial applications. The oil used in these transformers acts as an insulator, protecting the internal components from moisture, dust, and other contaminants that can cause damage over time. This helps to extend the lifespan of the transformer and reduce the need for frequent maintenance and repairs.

In addition to their efficiency and reliability, oil cooled transformers are also highly customizable to meet specific power requirements. Manufacturers offer a range of options for voltage levels, power ratings, and cooling methods to ensure that each transformer is tailored to the unique needs of the customer. This level of customization allows for greater flexibility in designing power distribution systems and ensures optimal performance in any industrial setting.

When it comes to sourcing oil cooled transformers for industrial applications, batch production is a common practice among manufacturers. Batch production involves producing a specific quantity of transformers at one time, which allows for greater efficiency and cost savings compared to producing each transformer individually. This method also ensures consistency in quality and performance across all units, providing peace of mind for customers who rely on these transformers for their operations.

Finding a reliable supplier for oil cooled transformers is essential for ensuring the success of industrial applications. A reputable supplier will have a proven track record of delivering high-quality transformers that meet industry standards and regulations. They will also offer comprehensive support services, including installation, maintenance, and technical assistance to help customers get the most out of their investment.

In conclusion, oil cooled transformers offer a range of benefits for industrial applications, including efficient heat dissipation, compact design, durability, and customization options. By choosing a reputable supplier that specializes in batch production, customers can rest assured that they are getting a reliable and cost-effective solution for their power distribution needs. Oil cooled transformers are a smart choice for any industrial setting looking to optimize performance and reliability.

| Type | Rated capacity (KVA) | Voltage combination(KV) | No-load losses(W) | Load losses(W) | No-load Current (%) | Short-circuit impedance (%) |

| SH15-M-30 | 30 | 6,6.3,10,10.5,11/0.4 | 33 | 630 | 1.50 | 4.0 |

| SH15-M-50 | 50 | 6,6.3,10,10.5,11/0.4 | 43 | 910 | 1.20 | 4.0 |

| SH15-M-63 | 63 | 6,6.3,10,10.5,11/0.4 | 50 | 1090 | 1.10 | 4.0 |

| SH15-M-80 | 80 | 6,6.3,10,10.5,11/0.4 | 60 | 1310 | 1.00 | 4.0 |

| SH15-M-100 | 100 | 6,6.3,10,10.5,11/0.4 | 75 | 1580 | 0.90 | 4.0 |

| SH15-M-125 | 125 | 6,6.3,10,10.5,11/0.4 | 85 | 1890 | 0.80 | 4.0 |

| SH15-M-160 | 160 | 6,6.3,10,10.5,11/0.4 | 100 | 2310 | 0.60 | 4.0 |

| SH15-M-200 | 200 | 6,6.3,10,10.5,11/0.4 | 120 | 2730 | 0.60 | 4.0 |

| SH15-M-250 | 250 | 6,6.3,10,10.5,11/0.4 | 140 | 3200 | 0.60 | 4.0 |

| SH15-M-315 | 315 | 6,6.3,10,10.5,11/0.4 | 170 | 3830 | 0.50 | 4.0 |

| SH15-M-400 | 400 | 6,6.3,10,10.5,11/0.4 | 200 | 4520 | 0.50 | 4.0 |

| SH15-M-500 | 500 | 6,6.3,10,10.5,11/0.4 | 240 | 5140 | 0.50 | 4.0 |

| SH15-M-630 | 630 | 6,6.3,10,10.5,11/0.4 | 320 | 6200 | 0.30 | 4.5 |

| SH15-M-800 | 800 | 6,6.3,10,10.5,11/0.4 | 380 | 7500 | 0.30 | 4.5 |

| SH15-M-1000 | 1000 | 6,6.3,10,10.5,11/0.4 | 450 | 10300 | 0.30 | 4.5 |

| SH15-M-1250 | 1250 | 6,6.3,10,10.5,11/0.4 | 530 | 12000 | 0.20 | 4.5 |

| SH15-M-1600 | 1600 | 6,6.3,10,10.5,11/0.4 | 630 | 14500 | 0.20 | 4.5 |

| SH15-M-2000 | 2000 | 6,6.3,10,10.5,11/0.4 | 750 | 18300 | 0.20 | 5.0 |

| SH15-M-2500 | 2500 | 6,6.3,10,10.5,11/0.4 | 900 | 21200 | 0.20 | 5.0 |