ZMJ POWER

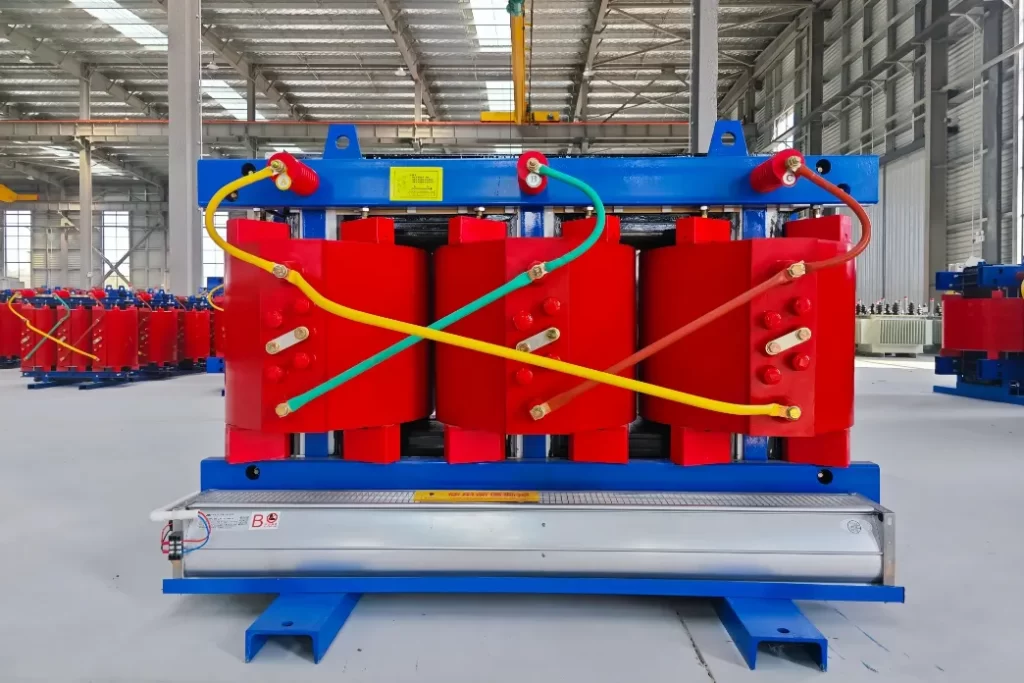

dry Type Transformer

Dry-type transformers are preferable for indoor installations, especially in locations where the risk of fire or environmental concerns related to oil leakage is a significant factor.

Technical Parameters

| Phrase | Three-phase |

| Rated Capacity | UP TO 20000 KVA |

| Rated Voltage | UP TO 40.5 KV |

| Secondary Voltage | 0.4 KV |

| Frequency | 50Hz / 60Hz |

| Winding Material | Copper / Aluminum |

| Iron Core | Cold-rolled Silicon Steel Sheet |

| Insulation Material | Resin |

| Standard | GB1094.1 (IEC60076) |

| Connection Symbol | Dyn11/Yyn0/YNd11 |

| Tapping Range | ±2×2.5%, ±5% |

| Insulation Class | F |

| Cooling Type | AN / AF |

| Running Environment | Highest temperature: +40℃ Highest daily average air temperature: +30℃ Highest annual average air temperature: +20℃ Lowest outdoor air temperature: -45℃ Altitude: ≤4000m |

| Protection Enclosure | IP00 – IP54 |

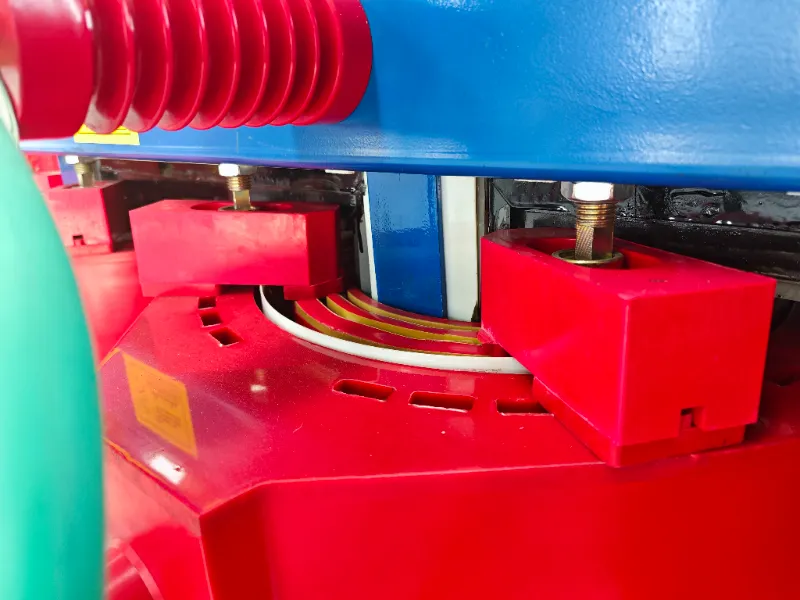

Product Details

Questions and Answers